Efforts to Enhance Product Usability

Developing Eye Drop Containers That Help Medical Treatments

We believe that eye drop bottles are not mere containers, but essential tools for treatment. Santen has been working to create the ideal bottle form that patients find truly usable. Listening to the voices of patients and medical professionals, from every angle we will continue to seek the best design for containers, to make them even easier to press and instill, and easier for users to distinguish the contents.

History Why Dimple?

What We Can Do as a Company Specializing in Ophthalmic Pharmaceuticals

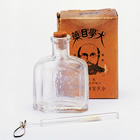

Santen’s commitment to developing the ideal container originated in 1899 in Japan, when the Company launched over-the-counter eye drops: Daigaku Eye Drops. To ensure excellent usability for this product, Santen developed a glass bottle with a cork stopple. Since no other products available then allowed users to instill liquid directly from the bottle, Santen’s container, as well as the eye drops, won high acclaim. In 1962, instead of conventional glass bottles, Santen employed plastic containers for its eye drops for the first time in Japan. Subsequently, Santen introduced various advanced technologies of the time from Western countries. For instance, the Company adopted sealed “bottle packed” containers for prescription eye drops during the 1970s, and tip-and-cap type containers with transparent caps on dropper tips during the 1990s. Santen’s researchers have always been seeking ways to help users, constantly asking themselves whether its containers are truly usable for patients. As a result, in 2002 they developed Dimple Bottles, featuring Santen’s original design.

History of Santen’s Eye Drop Bottles

| 1899 Glass Bottles | The first eye drops in Japan were marketed in 1867. Since then, containers have been constantly improving over the past century. Santen used glass bottles for its first eye drops. |

|

|---|---|---|

| 1962 Plastic Containers | As soon as plastics became a popular material for daily utensils, Santen developed plastic containers for its eye drops. Super Sante, Japan’s first eye drops in plastic containers, became a great hit thanks to how much easier they were to carry and to administer. The use of plastic containers was regarded as a “revolution in eye drop container design.” |

|

| 1977 “bottle packed” Eye Drops | To improve the safety of sterile eye drops, for the first time in Japan, Santen introduced the Blow/Fill/Seal (“bottle pack”) production system developed in Germany. This enabled container molding, solution filling, and sealing in a continuous process in a sterile, enclosed environment. Since the “bottle packed” containers had no spout openings when they were supplied to patients, this freed users from any concern about bacteria. |

|

| 1992 Tip-and-Cap | Santen introduced a tip-and-cap technology developed in the United States by improving the Blow/Fill/Seal system. In the new system, instead of providing a spout opening in the bottle body, each bottle has a dropper tip covered by a transparent cap, which keeps the container sealed tightly. |

|

| 2002 Dimple Bottles | Santen developed its original Dimple Bottle design after thorough studies of the ideal shape for containers in terms of usability. For instance, the new design makes it easier to hold the bottle, to remove the shrink film label, and to instill the solution. |

|

Innovation Dimple is Simple

Developing the Ideal Container-Easy to Distinguish, Handle, and Administer

Dimple Bottles have been developed in pursuit of a simple design, under the slogan: Dimple Is Simple. As compared with conventional containers, the new bottles are easier to distinguish, handle, and administer. The most outstanding feature of the new containers is the dimples on both sides. The dimples, whose shape fits the fingertips, make the container easy to hold. By pressing the sides gently, users can instill a fixed amount of liquid from the beginning to the end. The cap also has a design making it easy to grip and open with little force. Since eye drops are used on a daily basis, Santen has sought a universal design that allows any user to hold and use the products easily. Moreover, to enhance visibility, the product name is printed in larger characters on the label, and transparent slots are arranged on both sides of the bottle to facilitate checking the amount of solution remaining in the bottle. In 2008, Santen was honored with a Good Design Award in recognition of the Company’s efforts to promote universal design.

Future Dimple for the Smile

To Enable All Patients Worldwide to More Easily View the Product

Favorable evaluations of Dimple Bottles by both patients and medical professionals have convinced us that the containers meet most user needs. On the other hand, we are still faced with various challenges. For instance, we must further work to make the containers more distinguishable for users with low vision. In addition, we must address the growing demand for preservative-free drug formulation, as well as problems relating to production costs. Regarding the requirement to make products more visible and distinguishable, we have already begun various tests in cooperation with the Japan Low Vision Society*. We have also indicated our commitment to help patients outside Japan. Santen will continue to work to make our products more visible for low-vision patients around the world.

- Japan Low Vision Society

Founded in April 2000 with the aim of promoting interdisciplinary research on habilitation and rehabilitation of low vision people, as well as clinical trials. The Society also fosters friendships among its members and with members of overseas low vision societies. As of December 2011, the society has approximately 700 members.