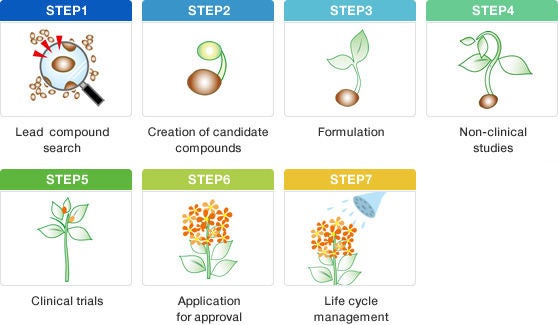

The first step in drug discovery is the search for lead compounds(*1) that can potentially be transformed into new drugs. This search involves sorting through natural ingredients from plants and microorganisms as well as artificially synthesized compounds. Testing hundreds of thousands of compounds is a time-consuming job that is not easily managed. When an idea for a new compound developed within the company, we have built a system to screen for suitable candidates through our own network with universities, research institutes, pharmaceutical companies, and startup companies worldwide.

The Ophthalmic Production Process: R&D

Santen’s ophthalmic products such as eye drops and injections are highly regarded by health care practitioners in Japan and around the world. Our R&D process starts with learning and understanding of the needs of patients and pathophysiology of the disease. With our aim to provide solutions that truly meet patients’ needs, we pursue drug discovery by following the steps below.

Searching for lead compounds

Finding the Genesis of New Drugs.

- A compound with a chemical moiety that causes promising biological activity and exhibits preferential pharmaceutical properties.

Determining compounds suitable for development

Selecting Development Candidates.

The discovery of a lead compound does not necessarily guarantee the creation of a new drug. The lead compound will undergo repeated chemical modification and evaluation to attain a higher level of safety and efficacy(*2). At this stage, we organize a team composed of experts in various fields to enhance research productivity. This team performs collaborative screening work and conducts numerous pharmacological and toxicity studies on derivatives of the lead compound to examine safety and efficacy. This process eventually results in the designation of compounds that can advance to the development phase.

- This process may be unnecessary in network-based drug discovery.

Formulation

Creating Drugs from the Best Molecular Compounds.

A compound that makes it to the development stage is slated to become the active ingredient for a pharmaceutical product. However, these compounds won't be therapeutically effective in their original state. The compound needs to be supplemented with additional substances in order to maximize its performance. The compound will be suitable for clinical use only after careful consideration of the types and mixing ratios of these additional substances as well as the optimal dosage form of the final product. Santen is currently employing cutting-edge DDS(*3) technologies such as Novasorb®(*4) and microspheres(*5) in our ongoing quest to develop drugs with higher efficacy and fewer side effects. We also conduct thorough tests to confirm active ingredient stability and formulation performance for the overall goal of designing products that will be safe and efficacious for all patients.

- Drug Delivery System. These systems guarantee the drug will travel to the proper place at the proper time. Liposomes and emulsions are two major types of DDSs.

- Novasorb is a technology used to produce emulsions containing positively-charged substances. Such emulsions adhere to the negatively-charged ocular surface through electrostatic attraction, and are anticipated to improve clinical efficacy and reduce side effects and administration frequencies.

- Made of synthetic or natural polymers, microspheres act as vessels that encapsulate and transport therapeutic compounds. They can be designed for sustained release of drugs at local sites or modified to particles several micrometers in diameter for accurate delivery to target tissues.

Performing non-clinical studies

The Path toward a Therapeutically Beneficial Drug.

Formulated ophthalmics undergo non-clinical studies using animal or in vivo models in order to estimate their effects on human physiology. This is where we see whether the compound leads to desired outcomes or whether any safety issues arise. We also test absorption, distribution, metabolism and excretion to examine how the compound acts under physiological conditions. In all of these activities, we follow the rigorous standards mandated by GLP(*6).

- Good Laboratory Practice, or a set of guidelines for non-clinical safety studies.

Performing clinical trials

Testing to Determine Whether a New Drug is Therapeutically Beneficial.

Compounds that have passed non-clinical studies advance to full-scale clinical trials where we investigate their effects on the human body. Clinical trials are divided into three phases. Phase I involves administration of the compound to a small group of healthy patients(*7). Phase II involves administration to a small group of patients experiencing different stages of the disorder the compound is designed to treat. This phase is used to analyze safety and performance, and can be beneficial in determining proper dosage and administration methods. Phase III involves administration to a large group of patients. Here, we study the efficacy and safety of the compound in comparison to existing treatments or a placebo. Santen’s global clinical R&D framework allows us to perform clinical trials in Japan, Europe, the United States and various countries in Asia, which is advantageous in expediting the application process for each region.

- Patients with the target disorder sometimes participate in this phase.

Gaining approval

The Final Test.

A compound can prove its safety and effectiveness in clinical trials, but it cannot be recognized as a drug unless it gains approval from the proper regulatory agency. In the case of Japan, we submit an application to the Ministry of Health, Labor and Welfare. A review board consisting of specialists chosen by the Ministry critically scrutinizes this application. When approval is granted, a safe and reliable ophthalmic drug is finally born.

Life Cycle Management

Active Monitoring of the New Approved Drug.

The new approved drug will be used by many patients who may react differently to its properties. Therefore, monitoring a new product once it enters the market is an important responsibility for pharmaceutical firms. There is always the chance that adverse reactions or even unanticipated benefits that went undetected during Phase III of the clinical trial may appear. Tasked with collecting clinical data after launch, Santen’s marketing division notifies our development division if any additional drug effects have been identified. This process of monitoring is called Life Cycle Management (LCM). We also perform post marketing surveillance to detect unforeseen adverse reactions. We examine the data and implement safety measures such as a review of the conditions the drug is authorized to treat and the method it is being administered. In this manner, Santen is dedicated to improving the quality of our existing products.