Santen seeks to provide appropriate control of chemical substances at every operational site that handles chemical substances.

In Japan, based on the Law concerning Pollutant Release and Transfer Register (PRTR) system to properly manage chemical substances that may pose risks to human health or ecosystems, companies are required to report emissions to the atmosphere and off-site transfers of substances that meet the criteria defined by the PRTR system.

Furthermore, we introduced a "system for controlling chemical substances" to provide centralized control of the amount released and stored and the location of storage, as well as to appropriately purchase and use chemical substances. In order to reduce the release of chemical substances into the air as well as to decrease the impact on the environment, we installed an instrument to recover organic solvents, and ensure that the performance of the instrument is maintained through inspection and maintenance of the instrument.

Environmental Load Reduction

Santen seeks to reduce environmental impact by taking measures to deal with the depletion of natural resources by converting to renewable raw materials and resources, contributing to solving water resource problems by efficiently using water resources in business activities and purifying wastewater, and preventing environmental pollution.

Detailed information on reducing environmental impact is disclosed in Environment Data.

Waste Reduction

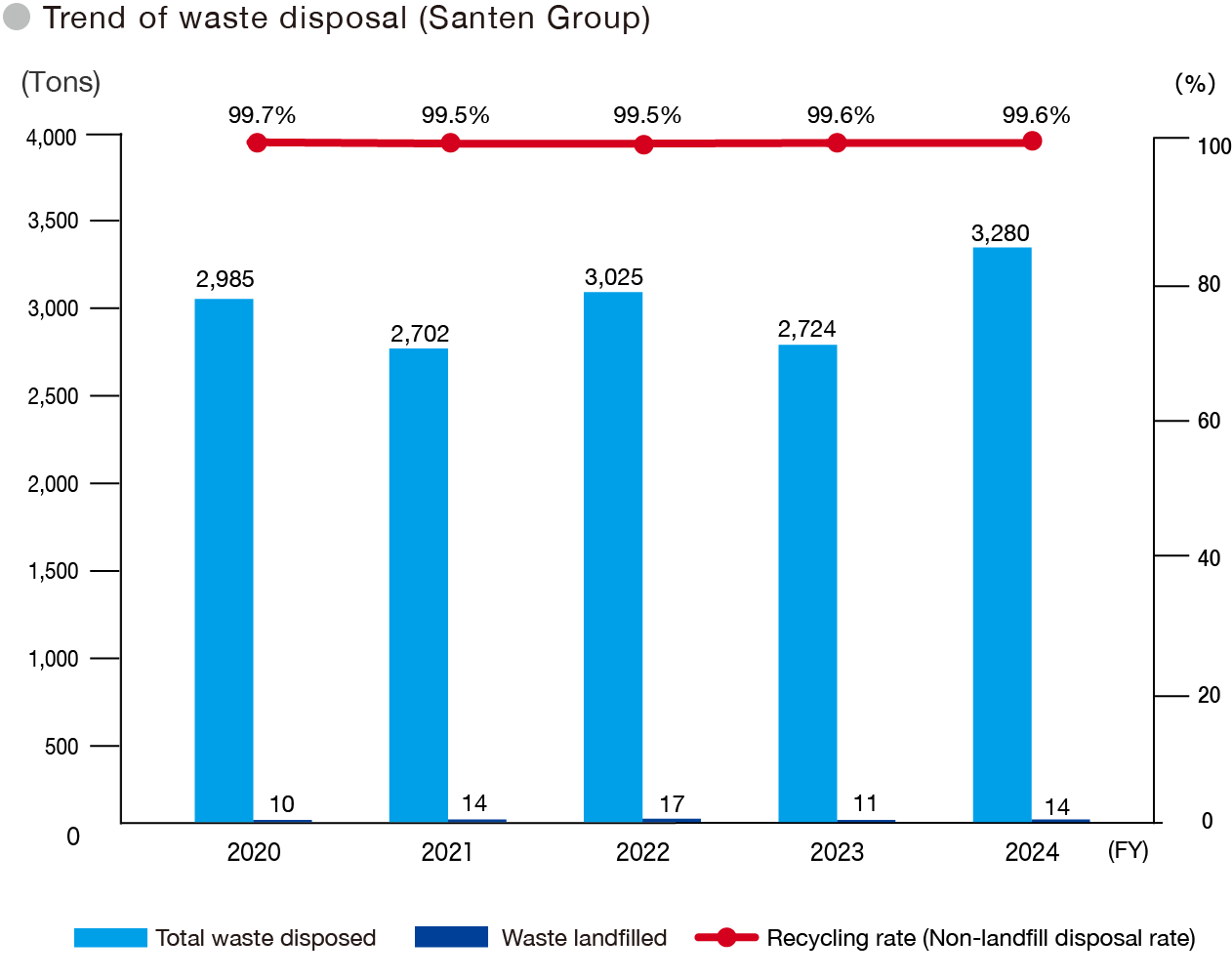

Santen promotes the 3R initiatives of "Reducing" the production of waste, "Reusing" packaging and stationery used during the distribution process, and "Recycling" waste by sorting, at each operational site. Before concluding an agreement with a new outsourced waste disposal service provider, we visit it and check that appropriate waste treatment is being conducted. Furthermore, we ensure that our waste is properly treated at our outsourced waste disposal service provider by confirming the waste policy, and the form of management of waste treatment, and by making regular visits to the service provider. The recycling rate (Non-landfill disposal rate) as a group was 99.6%, thus meeting the FY2030 target of 98% or higher.

Conservation of Water Resources

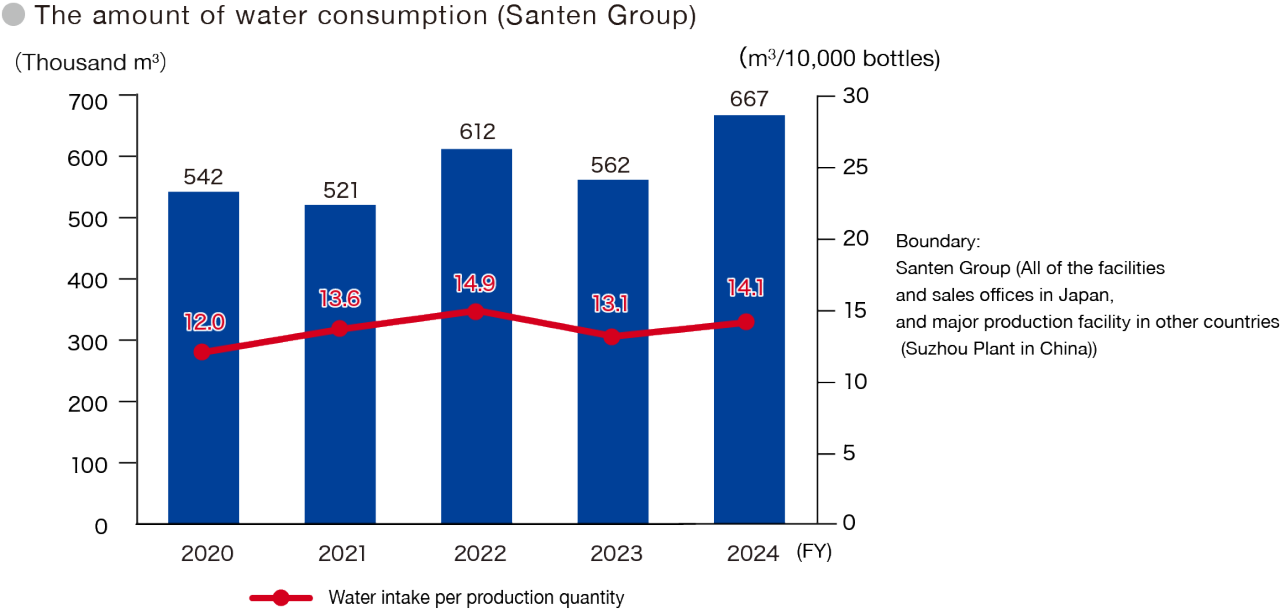

While no Santen plants or laboratories are located in areas under water stress(*), we view water as a precious resource and are striving to reduce our environmental impact by restricting water consumption by reusing wastewater for cooling or cleaning and other means. Due to the impact of the test operation at Suzhou Plant, water consumption per unit of production in FY2024 was 14.1 m3/10,000 bottles, an increase of 7.3% from the previous fiscal year.

- Under water stress: a condition in which the annual available water per person falls below 1,700m3, causing inconvenience in daily life

Appropriate Control of Chemical Substances

Organic solvent recovery equipment at Nara Research and Development Center

Prevention of Environmental Pollution

We regularly measure and analyze a variety of indices at each operational site, including air pollution, water contamination, and noise levels, in order to appropriately control and identify pollution levels according to the regulatory standards stipulated in laws and local regulations.

We also compile procedures to prevent the leakage of pollution and install equipment that prevents wastewater leaked from the storage container from flowing into the general discharge channel outside the plant and practice the operation thereof. We thereby establish a system to prevent impact on the environment and the surrounding communities.

Hazardous Waste Trend

We have defined "Hazardous Wastes", according to the laws and regulations of each country, as substances that fall under specially controlled industrial waste as stipulated in the "Waste Disposal and Public Cleansing Act" in Japan, and substances to be treated as dangerous waste in China. We started collecting data from FY2020.