Supply Chain

With the aim of promoting responsible procurement, Santen will ensure supply chain management and monitor its business partners to eliminate risks, including that of sparking boycott movements against the Group, and promote responsible procurement to improve the corporate value of our business partners and our company.

Sustainable Procurement Policy and Guidelines

With the aim of promoting sustainable procurement to enable us to contribute to the development of a sustainable society by fulfilling our social responsibilities in cooperation with our business partners, Santen has established a Sustainable Procurement Policy, and formulated the Santen Group Sustainable Procurement Guidelines, which define the rules the Group's business partners are advised to comply with in order to promote sustainable procurement.

Santen Group Sustainable Procurement Policy

To contribute to the development of a sustainable society by fulfilling its social responsibilities in cooperation with its business partners based on Santen's Core Principle "Tenki ni sanyo suru" in compliance with its Sustainability Policy, the Ten Principles of the United Nations Global Compact, etc., the Santen Group promotes sustainable procurement in the following ways:

Compliance with applicable laws and international norms

In a highly ethical manner, we will ensure fairness in selecting optimal suppliers and dealing with them in compliance with applicable laws and international norms.Ensuring an appropriate level of quality, efficacy and safety, and stable supply

We will ensure an appropriate level of quality, efficacy and safety of procured products and services, and their stable supply, and obtain necessary information for those purposes in a timely manner.Respect for human rights and prohibition of complicity in human rights abuses

We will respect the human rights of all people who are under the impacts of procured products and services, and never be complicit in human rights abuses.Protection of the rights, health and safety of workers

We will protect the rights of all those involved in producing and supplying procured products and services and assure their health and safety.Due consideration for environmental conservation

We will pay due consideration to environmental conservation in procurement activities and strive to prevent environmental pollution and reduce environmental burdens.Contribution to the development of a sustainable society

We will contribute to the development of a sustainable society by contributing to ophthalmic treatment using procured products and services.

- This policy has been approved by the Board of Directors.

Defining Critical Suppliers

Santen always takes a patient-centric perspective. To designate critical products in full consideration of their influence on patients, we have defined Santen products that have a 50% or higher market share that are vital to patients (*) as our "critical products" from the perspectives of 1) the availability of alternative products and 2) their impacts on patients. Moreover, we have defined suppliers of intermediate products that are necessary for us to provide patients with our critical products-including contract manufacturing organizations (CMOs), raw material suppliers, and contract service providers in charge of packaging, labelling, sterilization, etc.-as "critical suppliers."

- Products that are vital to patients: Treatments and diagnostic agents for serious diseases without which patients could not receive surgery or would lose their vision

Conducting a Supplier Assessment

Santen conducts a Supplier Assessment to identify potential risks in its supply chain. In the assessment, we show suppliers the Santen Group Sustainable Procurement Policy and Guidelines and request them to complete the Guidelines Compliance Questionnaire to confirm their efforts to follow the guidelines. This ESG survey is defined as an official process that all suppliers must undergo at the beginning of their contracts with Santen and in a common three-year cycle afterward. It is being considered not to extend contracts with suppliers if the minimum ESG requirements are not met, and to give preference to suppliers with superior ESG initiatives.

These efforts are reported to the Sustainability Committee and are raised with the Board of Directors as necessary.

Supplier screening

| FY2024 | |

|---|---|

| Total number of Tier-1 suppliers | 139 |

| Total number of significant suppliers in Tier-1 | 119 |

| % of total spend on significant suppliers in Tier-1 | 96.5% |

| Total number of significant suppliers in non Tier-1 | 32 |

| Total number of significant suppliers (Tier-1 and non Tier-1) | 151 |

Risk Management on Supply Chain

To continue steadily supplying our products even if our supply chain faces various risks, including those of accidents, natural disasters, and climate change, Santen recognizes the necessity of risk management throughout our supply chain, such as building a backup system with multiple plants and procuring raw materials from multiple suppliers.

Supplier-related sustainability risks in the stable supply of pharmaceuticals are primarily interruptions in the supply of raw materials from critical suppliers. For example, suppliers may be subject to production discontinuation orders from regulatory authorities due to deviations from manufacturing and quality control standards or legal compliance, environmental protection or health and safety issues.

We recognize and manage risks comprehensively by identifying critical suppliers in terms of transaction volume, important raw materials, and the absence of alternative suppliers.

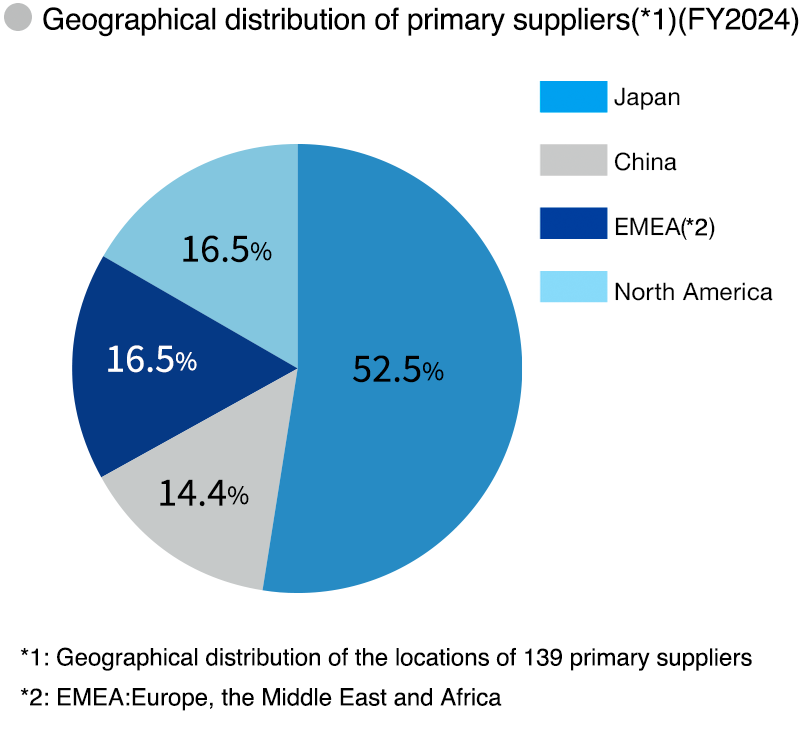

Geographical distribution of Suppliers

To ensure stable procurement, Santen grasps and manages the geographical distribution of suppliers in its supply chain.

Building Healthy Relationships with Suppliers

With the belief that our suppliers are our partners essential for providing patients with medical and pharmaceutical products and the like, Santen strives to enhance our product quality and carry out improvements to cut prime costs through mutual exchanges and cooperation, as well as complying with the Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors, and maintaining the secrecy of provided information, with the aim of building relationships that enable both parties to develop in a sustainable manner.

Santen has internal regulations, including the Regulations on Purchasing Management, providing that the selection of suppliers requires making competitive estimates and comprehensively evaluating candidates in terms of product quality, delivery periods, managerial reliability, etc. Concerning the prevention of conflict of interest, the Code of Conduct in the Santen Code of Practice provides against the receipt of profits provided by business partners.

In addition, with the aim of building new partnerships and coexistence and co-prosperity relationships throughout the supply chain, we endorse the main purpose of the "Declaration of Partnership Building" established by the "Conference on Promoting Partnership Building for the Future" promoted by the Cabinet Office, the Small and Medium Enterprise Agency, and others, and we disclose our declaration of partnership building.